Manual 07 for MD++

Calculating Elastic Constants

Keonwook Kang and Wei Cai

Elastic constants are physical properties of crystals to relate the mechanical response to the material deformation (i.e. stress and strain) within elastic regime. To calculate the elastic constants is one simple way of validating a potential model. There are two methods to compute elastic constants: one is to monitor (Virial) stress and the other is to monitor strain energy as a function of the applied strain. Conceptually, the two approaches are equivalent except that stress is a linear function of strain and the strain energy is a quadratic function of strain. In this manual, both methods will be explained to get three independent elastic constants(C11, C12 and C44) for the cubic crystal materials, e.g. silicon.

Contents |

Using Virial Stress

If Virial stress is available to compute, the task of obtaining elastic constants is relatively easy. In crystals with cubic symmetry, there are three independent elastic constants: C11, C12 and C44. C11 is the proportional constant between the stress σ11 and the strain ε11, and C12 is the proportional constant between the stress σ22 and the strain ε11. We can get C11 and C12 from one simulation by applying strain ε11 and monitoring two components of stress σ11 and σ22. MD++ script si_elastic.script is given below.

# -*-shell-script-*-

# Calculate Elastic Constants of Si

# setnolog

setoverwrite

dirname = ~/Codes/MD++/runs/si_elastconst

#--------------------------------------------

#Create Perfect Lattice Configuration

crystalstructure = diamond-cubic

latticeconst = 5.430953e+00 #(A) for Si

latticesize = [ 1 0 0 3

0 1 0 3

0 0 1 3]

makecrystal

#-------------------------------------------------------------

#Conjugate-Gradient relaxation

conj_ftol = 1e-4 conj_itmax = 1000 conj_fevalmax = 1000

conj_fixbox = 1

eval relax eval finalcnfile = relaxed.cn writecn

#-------------------------------------------------------------

conj_fixbox = 1 #conj_monitor = 1 conj_summary = 1

input = [ 1 1 0.001 ] shiftbox relax eval

input = [ 1 1 9.99000999000999e-04 ] shiftbox relax eval

input = [ 1 1 9.98003992015968e-04 ] shiftbox relax eval

input = [ 1 1 9.97008973080758e-04 ] shiftbox relax eval

input = [ 1 1 9.96015936254980e-04 ] shiftbox relax eval

quit

You can run the script by typing

$ bin/sw gpp scripts/si elastic.script

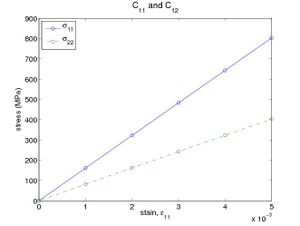

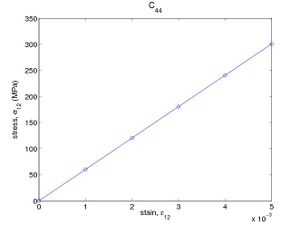

The above script first generates a 3 × 3 × 3 perfect diamond cubic structure of Si. It then applies tensile strain in increments of 0.1% along [100] direction by the command shiftbox, and calculate the corresponding Virial stress at each strained state by the command eval. From the log file, the stress components σ11 and σ22 can be obtained and plotted as a function of the applied strain ε11. Fig. 1(a) plots the result from running the script with Stillinger-Weber(SW) potential. The slopes of these lines give C11 = 160.6 (GPa) and C12 = 80.5 (GPa).

To compute C44, which is the proportional constant between σ12 and ε12, we can simply insert the following lines before quit in the above script.

incnfile = relaxed.cn readcn input = [ 1 2 0.001 ] shiftbox relax eval input = [ 1 2 0.001 ] shiftbox relax eval input = [ 1 2 0.001 ] shiftbox relax eval input = [ 1 2 0.001 ] shiftbox relax eval input = [ 1 2 0.001 ] shiftbox relax eval

These commands shear the crystal in increments of ε12 = 0.1%. Again, from the log file, the stress component σ12 can be obtained and plotted as a function of the applied strain. The result from SW potential is plotted in Fig. 1(b), from which we obtain C44 = 60.2(GPa). The values for C11 , C12 , and C44 obtained here are consistent with the original paper.<ref>H. Balamane, T. Halicioglu, and W. A. Tiler, PRB 46 2250-2279</ref>

- Fig.1

Using the potential energy

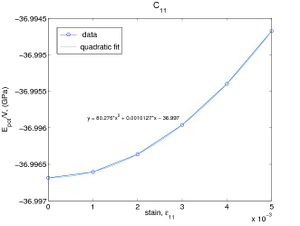

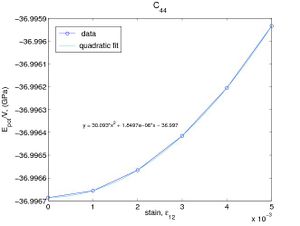

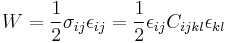

Sometimes, the simulation code does not implement the Virial stress calculation. In ab initio simulations, the Virial stress is usually not very accurate. In these cases, we can compute the elastic constants by monitoring the potential energy of the system, because the strain energy density W is defined as

. .

|

If the only nonzero strain is ε11, then the streain energy per volume becomes W = C11ε2 / 2. We can determine C11 by fitting W(ε11) to a parabola as shown in Fig.2(a). The elastic constnat C44 can be determined in a similar way as shown in Fig.2(b). The elastic constants obtained in this way are C11 = 160.5(GPa) and C44 = 60.2(GPa), which are almost the same as the results obtained by using Virial stress.

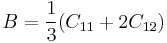

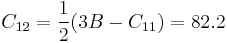

The elastic constant C12 is easily determined by the elastic relation

|

where B is the bulk modulus, which we have already calculated in the manual 03. Since the bulk modulus of silicon is 108.3 (GPa) with SW potential, the elastic constant C12 is

(GPa) (GPa)

|

- Fig.2

Finding shear elastic constant for a non-tilting simulation cell

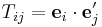

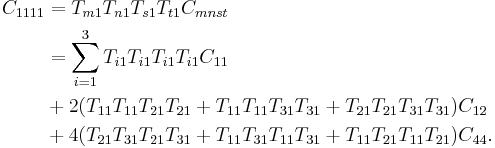

In the above sections, we compute C44 by shearing the simulation cell. The simulation cell was rectangular before the shear, but becomes tilted after the shear. However, sometimes a simulation code allows to use only a rectangular simulation box and we can not tilt the box at all. In this case, how can we find the shear elastic constant C44? Notice that C11 and C12 can be always obtained with a rectangular cell, when the repeat vectors of the cell are aligned with the cubic axes of the crystal. With C11 and C12C12 known, we can determine C44 using the orthogonal transformation rule for the 4th order tensor. When the repeat vectors are not aligned with the cubic axes, we should be able to compute linear combination of C11, C12 and C44 while keeping the simulation cell rectangular. Remember that C11, C12 and C44 are components of a 4th order tensor which transforms as

| Cijkl = TmiTnjTskTtlCmnst |

where  is relation between two coordinate systems

{

is relation between two coordinate systems

{ } and {

} and { }.

}.

For example, if we have one coordinate system  = [1 0 0],

= [1 0 0],

= [0 1 0] and

= [0 1 0] and  = [0 0 1],

and another coordinate system

= [0 0 1],

and another coordinate system  = [1 1 0]/ \sqrt{2},

= [1 1 0]/ \sqrt{2},

= [−1 1 0]/ \sqrt{2} and

= [−1 1 0]/ \sqrt{2} and  = [0 0 1],

then the matrix [T] is

= [0 0 1],

then the matrix [T] is

![[T] = \begin{pmatrix} 1/\sqrt{2} & -1/\sqrt{2} & 0 \\

1/\sqrt{2} & 1/\sqrt{2} & 0 \\

0 & 0 & 1 \end{pmatrix}](/mediawiki/images/math/e/8/6/e86bcdcb90d6ed8c857721e3d272e107.png)

|

In particular,

|

Suppose we create a perfect crystal such that x, y, and z axes of the simulation

cell are aligned with  ,

,  and

and  .

Then by straining the crystal along x axis,

we can obtain <maht>C'_{1111}</math> = 180.4 (GPa) using the SW potential. Given C11 = 160.6,

C12 = 80.5, the matlab script below gives C44 = 59.9(GPa) for silicon.

.

Then by straining the crystal along x axis,

we can obtain <maht>C'_{1111}</math> = 180.4 (GPa) using the SW potential. Given C11 = 160.6,

C12 = 80.5, the matlab script below gives C44 = 59.9(GPa) for silicon.

% With given C11, C12, and C1111’, find C44 in cubic materials.

% C11, C12, and C44 are the elastic constants in Cartesian

% coordinate system.

% C1111’ is the elastic constant in the new coordinate.

syms C11 C12 C44

C11n = 160.6; C12n = 80.5; C44n = 60.2;

C1111prime = 180.40;

xyz0 = [ 1 0 0; % original coordinate

0 1 0;

0 0 1 ];

xyz1 = [ 1 1 0; % new coordinate

-1 1 0;

0 0 1 ];

T = zeros(3,3);

for i=1:3

for j=1:3

T(i,j) = dot(xyz0(i,:),xyz1(j,:)/norm(xyz1(j,:)));

end

end

p=1; q=1; r=1; s=1;

A = T(1,p)*T(1,q)*T(1,r)*T(1,s) + T(2,p)*T(2,q)*T(2,r)*T(2,s) + ...

T(3,p)*T(3,q)*T(3,r)*T(3,s);

B = T(1,p)*T(1,q)*T(2,r)*T(2,s) + T(1,p)*T(1,q)*T(3,r)*T(3,s) + ...

T(2,p)*T(2,q)*T(3,r)*T(3,s);

C = T(2,p)*T(3,q)*T(2,r)*T(3,s) + T(1,p)*T(3,q)*T(1,r)*T(3,s) + ...

T(1,p)*T(2,q)*T(1,r)*T(2,s);

CC = A*C11 + 2*B*C12 + 4*C*C44;

cc = subs(CC, C11, C11n); cc = subs(cc, C12, C12n);

disp(sprintf(’C44 = %f’,double(solve(cc-C1111prime,C44))))