Introduction

Frank-Read source is a type of dislocation multiplication mechanism. Consider a segment whose ends are pinned (corresponding to nodes in a network, precipitates, or sites where the dislocation leaves the glide plane). Under a certain applied stress the segment bows out by glide. As bow-out proceeds, the radius of curvature of the line decreases and the line-tension forces tending to restore the line to a straight configuration increase. For stress less than a critical value, a metastable equilibrium configuration is attained, in which the line-tension force balances that caused by the applied stress. For the large bow-out case, following equilibrium condition holds:

![b\mathbf{\sigma} = \frac{\mathbb{S}}{r}=\frac{\mu b^2}{4\pi r\left( 1-\nu\right)} \left \{ \left [ 1- \frac{\nu}{2} \left ( 3-4 \cos^2\beta \right ) \right ] \mathrm{ln} \frac{L}{\rho} -1 + \frac{\nu}{2} \right \}](/mediawiki/images/math/5/1/1/511e8e53e6042ade1883a4957c86ba88.png)

(Hirth-Lothe, p. 752)

where r is the radius of the loop. The radius of the curvature is a minimum when r = L / 2. Hence the maximum stress for which local equilibrium is possible is given by the equation above with r = L / 2. For the typical case that L = 103ρ and μ = 0.33, the critical stress for a dislocation initially pure edge and pure screw, respectively, is σ * = 0.5μb / L and σ * = 1.5μb / L.

When the net local resolved shear stress( the applied stress plus the internal stresses) exceeds σ * , the loop has no stable equilibrium configuration but passes through the successive positions. Provided that the expanding loop neither jogs out of the original glide plane because of intersections with other dislocations nor is obstructed from rotating about the pinning point, it will annihilate over a portion of its length, creating a complete closed loop and restoring the original configuration. A sequence of loops then continues to form from the source until sufficient internal stresses are generated for the net resolved shear stress at the source to drop below σ * .

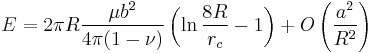

To compare the analytic result with DDLab simulation, we need to use the relation ρ = rc / 2. According to the non-singular continuum theory of dislocation (JMPS 54, 561-587, 2006), the energy of a circular prismatic dislocation loop is

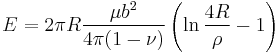

According to Hirth and Lothe, the energy of the same loop is,

Therefore

Reference: J. P. Hirth and J. Lothe, Theory of Dislocations", 2nd ed. (Wiley, New York, 1982)

DDLab Input Parameter

DDLab has included a sample Frank-Read Source input file in its latest version (2008 January) at ~/Inputs/input_frank_read.m. Following is a brief introduction to some parameters important to Frank-Read source test.

1. rn--it gives the initial coordinations of nodes. The default setting is a straight dislocation line pinned (tag=7) at (1200,1200,1200) and (-1200,-1200,-1200) with a mobile (tag=0) node in the middle, (0,0,0). Of course, 1200 can be substituted into arbitrary numbers when we investigate the influence of initial segmental length.

2. links--a data structure which gives the information of dislocation segment connectivity, burgers vectors( [0.5 0.5 0.5] default ) and glide planes (-1,1,0) default ).

3. totalsteps--number of cycles that are run for completion of dd3d command. It should be large enough to secure dislocation configuration has arrived at its equilibrium configuration, for example, 1000 or above.

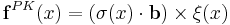

4. appliedstress--external applied stress in the form of 3*3 symmetric tensor. Peach-Koehler formula will be needed to give the exact force on each segment, i.e.

5. a--dislocation core radius used for non-singular force calculation, sometimes written as rc.

6. plotfreq--number of cycles between monitered node write statements, higher number makes observation simpler. When the dislocation line goes beyond plotting limits, simply Increasing plim can provide a better view.

7. lmin and lmax -- minimum and maximum length of a dislocation segment for remeshing. The shorter segments are, the smoother dislocation line becomes.

8. mobility --mobility law based on which dislocation responds to forces (mobbcc0 for BCC, which is the default setting; mobfcc1 for FCC). For FCC crystals, glide plane is uniquely defined rather BCC, i.e. dislocation motion is confined to a preferred plane.

We can manipulate these parameters to investigate Frank-Read Sources via DDLab.

F-R Test

1. Criteria to define σ *

In the case of Frank-Read source, It is difficult to give a quantitative definition on critical applied stress. When totalsteps is large enough, the bowing process will eventually stop unless that critical stress has been reached. Let's define a certain geometric configuration beyond which the dislocation line becomes unstable and keeps growing, even forming loops. When such configuration is formed, we denote the current external applied stress as the critical one. It is convenient to use maximum distance criteria, that we can extract the coordinates of all nodes from rn and find out the maximum distance from the center of initial dislocation line. If the maximum distance exceeds an empirical value, let's say, L, which is the length of initial dislocation line, we can regard the configuration as "critical" and determine the critical stress, σ * . Several trials have proven that L is a safe one. As long as totalsteps is large enough, 2L, 4L etc will also work well.

3. Basic settings

The initial dislocation line is pinned at (-l,-l,-l) ,(l, l, l). (0, 0, 0) is a mobile node at the center.

Burgers vector is [0.5, 0.5, 0.5] in the medium and the glide plane is (-1, 1, 0).

The external stress is [2 0 1; 0 2 -1; 1 -1 0] times a certain value.

rn = [ 1000 1000 1000 7; -1000 -1000 -1000 7; %pinned at two ends 0 0 0 0]; %mobile node in the middle links = [1 3 0.5 0.5 0.5 -1 1 0; 3 2 0.5 0.5 0.5 -1 1 0]; %burgers vector [0.5 0.5 0.5], glide plane (-1 1 0) MU = 1; NU = 0.305; %elasticity constants for isotropic media maxconnections=8; lmax = 1000; lmin = 200; % fixed lmax and lmin for all cases areamin=lmin*lmin*sin(60/180*pi)*0.5; areamax=20*areamin; a=lmin/sqrt(3)*0.5; %defined in terms of lmin Ec = MU/(4*pi)*log(a/0.1); %Ec=0 when compared with analytical expression totalsteps=200; %enough for rough estimations dt0=1e7; mobility='mobfcc1'; %FCC mobility law %Drag (Mobility) parameters Bscrew=1e0; Bedge=1e0; Beclimb=1e2; Bline=1.0e-4*min(Bscrew,Bedge); integrator='int_trapezoid'; rann = 0.5*a; rntol = 0.5*rann; doremesh=1; docollision=1; doseparation=1; elasticinteraction=1; %line tension model when this is zero plotfreq=1; plim=10000; appliedstress =1e-3.*[2 0 1; 0 2 -1; 1 -1 0]; % a value times a stress tensor viewangle=[45 -45]; printfreq=1; %set as 10 for better view printnode=3; rmax=100;

2. Algorithm

3. Basic setting

4. Investigation

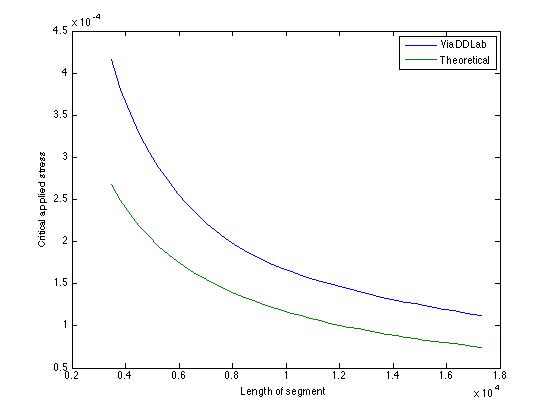

Based on the maximum distance criteria, we can easily determine the critical applied stress for different initial straight line lengths. Here is a graph showing the relationship between σc and L.

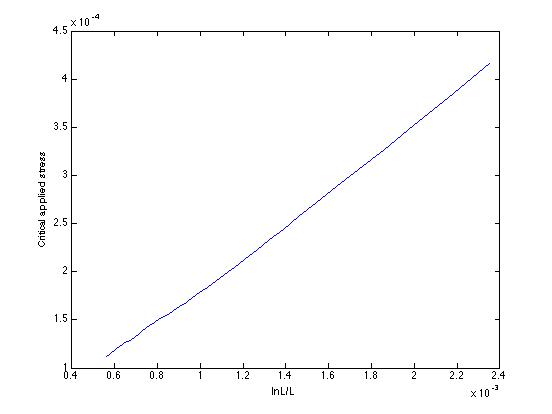

Currently there is some deviation from the theoretical value of critical applied stress; however, we can clearly see the linear relationship. Following figure shows the critical applied stress is linearly dependent on lnN/N.

By varying a, which is the core radius, we can derive the critical stresses and find its linear dependence on ln a, as long as L is fixed.